The shaped casting shop of “Baku Steel Company” CJSC is a specialized section for the production of cast iron and steel parts for oil industry equipment used both in the country and abroad.

The shaped casting shop consists of the following areas:

- Model shop: In this shop, the model of cast iron and steel orders entering the enterprise is made of wood material.

- Sand drying and sand (foundry) mixture preparation area: here the sand is dried in a heating drum and then transported to the area of preparation of the sand mixture. Sand mixture is prepared in special mixers using dry silica sand, liquid glass, and water-soluble alkali. When ready, the mixture is transported to moulding and casting shop via the conveyor belts. This sand mixture is filled in bunkers and used for moulding various details manually, or using moulding machines. The sand mixture is shaped in the casting boxes, and upper and lower half-moulds are dried in drying chambers.

- Filling area: in this area, a specially prepared mixture is used for the filling of moulds, which are then dried in heating chambers. Cast upper and lower half-moulds are cleaned with compressed air, and painted with fire-resistant paint, upper and lower half-moulds are then put together, fixed, and prepared for pouring of liquid metal. Metal is melted in a 4-ton induction furnace in the casting area, then melt liquid is poured into a metal ladle.

- Shaking area: here the cast details are extracted from the burnt sand mixture and sent to the cleaning area. Details are cleaned from the soil in the cleaning area, then completely cleared by sandblasting method, and afterward sent for sale.

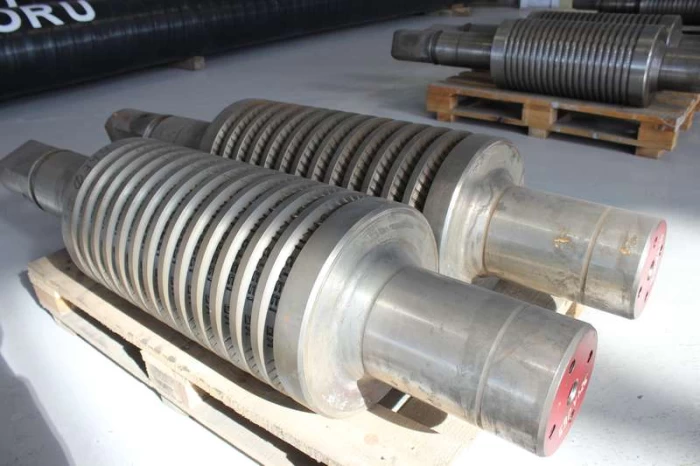

- Shaped casting area: this area is used for the preparation and casting of rollers of various sizes. Cast rollers are sent to the heating furnace. Annealing followed by normalizing and tempering is performed.

What are shaped castings?

Shaped casting is a special casting process used to create metal parts with complex shapes and intricate details. Unlike traditional casting methods, shaped casting is custom made to the specific shape and design of any part. Since shaped castings enable the production of metal parts with complex shapes and high dimensional accuracy, they are indispensable for performing a versatile and precise manufacturing process.

Shaped castings and their advantages

Shaped castings have many advantages, which can be listed as follows:

1. They allow the production of parts with complex geometries.

2. Ensures high dimensional accuracy and repeatability.

3. Can be cost effective for large production volumes.

Shaped castings facilitate the manufacture of the part to be produced to exact specifications using custom-made molds.

Shaped Casting Prices

You can contact us to get acquainted with the prices of shaped castings. The steelmaking enterprise, which produces the best repair and construction material in the country, offers you high-quality, durable and stable, shaped castings that meet modern standards.